SAM-UK are a professional manufacturer in producing vinyl building profile products and PVC,CPVC, PP ,PPR pipes and pipe fittings, valves, taps and so on .We own the certificates of SGS\SONCAP\ISO9001\CE\NSF.

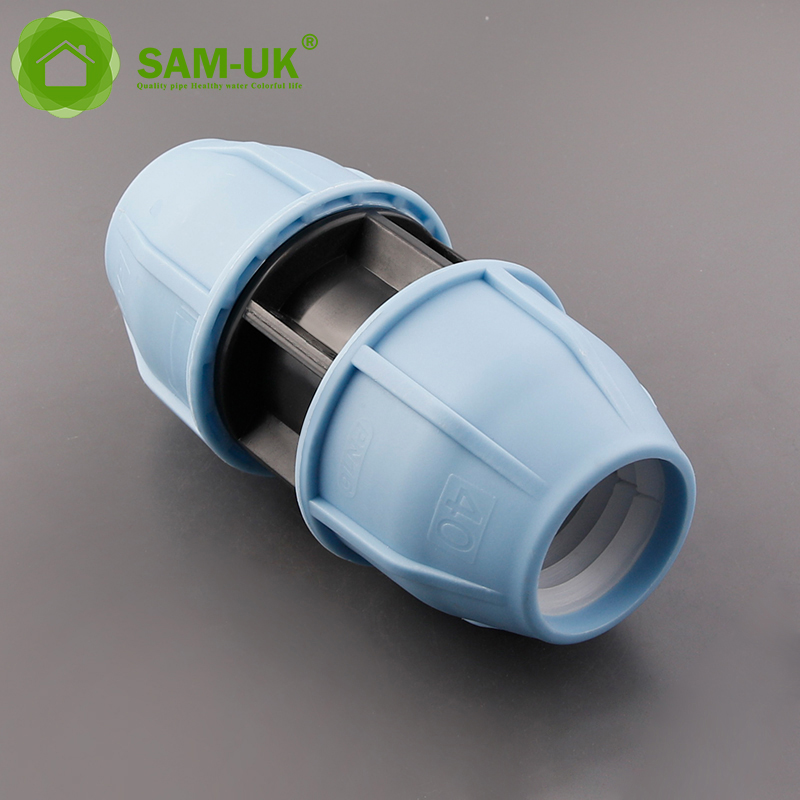

PP pressing joint has novel structure, easy installation and use, especially suitable for pipeline maintenance.

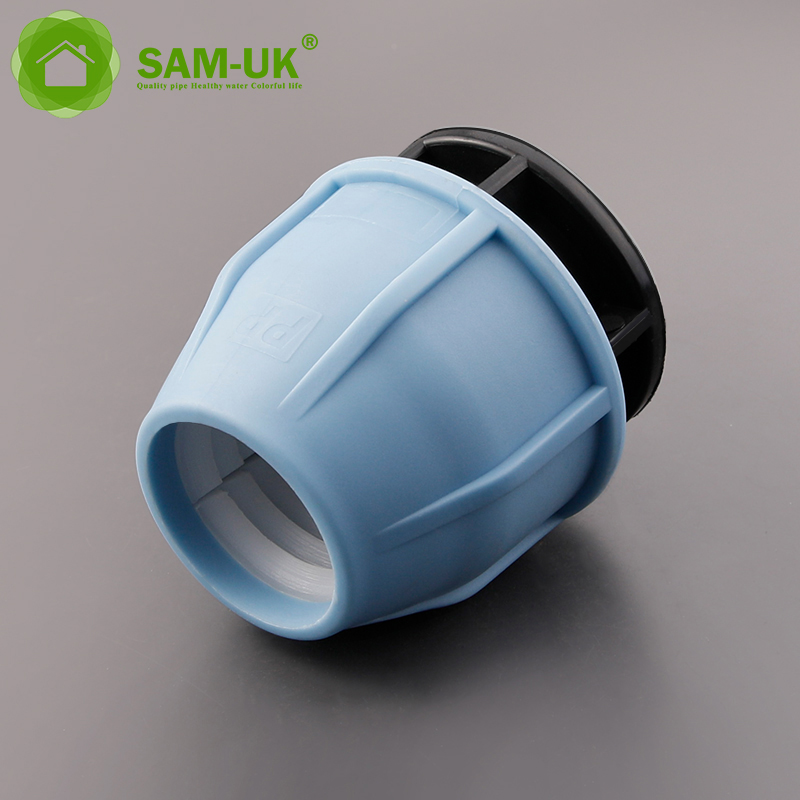

The PP compression joint is composed of a pipe fitting body, a locking nut, a pipe clamp and a V-shaped sealing ring. When in use, the nut and pipe clamp are placed on the pipe in turn, the pipe is inserted 4-5cm into the pipe body through the V-shaped sealing ring, and then the locking nut is tightened.

Because the PP pressing joint is sealed with V-ring, it has strict requirements for the roundness of the pipe, and is suitable for the installation of straight pipe.

Product features:

- PP pressing joint is composed of many parts, connected to each other, no water leakage.

- PP pressing joint connection, disassembly, flexible, easy to recycle.

- PP sleeve specifications are complete, can be divided into such straight through, different straight through, straight through tee, pp sleeve reducing tee, internal thread tee, external thread tee, pp sleeve elbow, internal and external thread joints, plugs, etc. In size there are basically Φ20, Φ25, Φ32, Φ40, Φ50, Φ63, Φ75, Φ90, Φ110 and other specifications, Can meet different construction sites.

- Pressure 1.6Mpa

Comparison of PP pressing joint with other pipe fittings:

1. PP pressing joint:

(1) Low labor cost and moderate pipe fitting price.

(2) No special mechanical equipment is required.

(3) Generally applicable to dn≤160mm pipe, can withstand small pressure.

(4) The construction is convenient, simple and fast.

2, PE butt welding pipe fittings:

(1) High labor costs and moderate pipe fitting prices.

(2) Special hot melt equipment (large capacity) is required.

(3) It is generally suitable for pipelines with DN≥50mm, and can withstand pressure of 1.25Mpa and 1.6Mpa.

(4) Often affected by the external construction environment, construction conditions are poor, and the construction progress is slow.

(5) The alignment deviation of the two pipe diameters shall not exceed 10% of the pipe diameter, and the small pipe diameter DN≤90 is difficult to master, and the small pipe diameter is not very useful.

- PE socket hot melt pipe fittings:

(1) High labor costs and low pipe fitting prices.

(2) Special hot melt equipment (small volume) is required.

(3) Generally suitable for DN≤110mm pipeline, can withstand 1.6Mpa pressure.

(4) Often affected by the external construction environment, construction conditions are poor, and the construction progress is slow.

(5) The connection process is simple and easy to learn, the cost of pipe fittings is low, and it is widely used in large-scale projects. - PE welding fittings:

(1) Low labor cost and high pipe fitting price.

(2) Special melting equipment (moderate volume) is required.

(3) Generally suitable for dn≥50mm pipeline, can withstand greater pressure.

(4) Convenient construction, less affected by the external environment, more convenient use.

(5) It is often used for emergency repair or when the hot melt welding machine cannot be placed.