Article Introduction

They look pretty similar. They’re both made from the same form of unplasticised PVC (PVC-U) but the difference is in the wall thickness. Schedule 40 upvc pressure pipes and fittings are made with thicker walls that stand up to low pressure applications. Whereas PVC DWV piping has thinner walls and is not made for pressurized applications.

Are PVC pressure pipe and PVC DWV pipe the same?

Sometimes there can be confusion over them and it’s easy to understand why. They look pretty similar. They’re both made from the same form of unplasticised PVC (PVC-U) but the difference is in the wall thickness.

- Schedule 40 pressure pipe are made with thicker walls that stand up to low pressure applications.

- Whereas PVC DWV piping has thinner walls and is not made for pressurized applications.

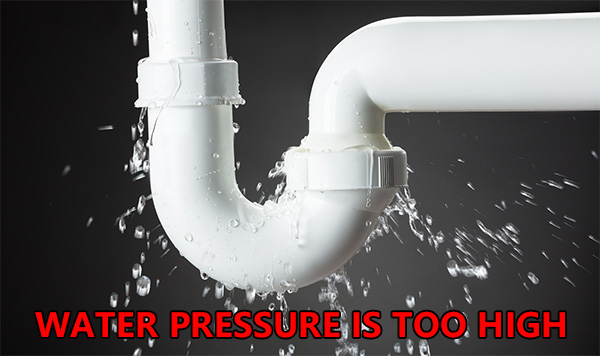

Another thing that can cause confusion sometimes is the end types. Usually both types of pipes are slip fitting, but some PVC DWV pipes and fittings schedule 40 upvc high pressure pipes & fittings are made with threading and to the same size as each other. Because of this they’ll fit together, but it’s not recommended.

Attention:Using them together in the same piping system can lead to major problems. It could even end in disaster if non-pressure pipes end up being used in pressure applications.

What are the main differences between PVC pressure pipe and DWV pipe?

PVC pressure pipe and PVC DWV pipe (Drain, Waste, and Vent) look similar, but they’re designed for very different purposes. Here’s a clear breakdown of their main differences 👇There are a number of main differences between PVC DWV pipe and schedule 40 high pressure plastic pipe fittings.

🧱 1. Purpose / Application

| Type | Primary Use |

|---|---|

| PVC Pressure Pipe | Designed to carry pressurized fluids such as potable water, irrigation, or industrial liquids. |

| PVC DWV Pipe | Used for non-pressurized systems — draining wastewater, venting plumbing fixtures, and sewer lines. |

⚙️ 2. Pressure Rating

| PVC Pressure Pipe | Rated for internal water pressure (commonly 160–450 psi depending on class or schedule). |

| PVC DWV Pipe | Not pressure-rated — it only handles gravity flow and venting air. |

🧪 3. Wall Thickness

| PVC Pressure Pipe | Has thicker walls to withstand internal pressure. Often marked as Schedule 40, Schedule 80, or Class 125/200/315. |

| PVC DWV Pipe | Has thinner walls (lighter weight) since no internal pressure is expected. Commonly marked ASTM D2665. |

🧩 4. Joint Type

| PVC Pressure Pipe | Uses solvent-welded or threaded joints that form watertight, pressure-tight seals. |

| PVC DWV Pipe | Uses solvent-welded or rubber gasket (hub and spigot) joints for easy installation and cleaning. |

🧰 5. Markings and Standards

| PVC Pressure Pipe | Marked with standards like ASTM D1785 (Sch 40/80) or ASTM D2241 (pressure-rated). |

| PVC DWV Pipe | Marked with ASTM D2665 (DWV systems). |

⚪ 6. Color and Appearance

| PVC Pressure Pipe | Usually white or gray, with pressure ratings printed on the side. |

| PVC DWV Pipe | Usually white, often with “DWV” printed clearly along the pipe. |

🚫 7. Can You Mix Them?

Not recommended.

DWV pipe should never be used where pressure is present — it may burst or fail.

Pressure pipe can technically be used in DWV systems, but it’s more expensive and heavier, so usually unnecessary.

What are the applications in PVC pressure pipe and DWV pipe?

Here’s a clear breakdown of the applications for both types of PVC pipe 👇

🚰 PVC Pressure Pipe – Applications

Used where water or fluid is under pressure:

- Potable (drinking) water supply – municipal and domestic water systems.

- Irrigation systems – agricultural and landscaping water delivery.

- Industrial fluid transport – chemicals, cooling water, and process fluids.

- Swimming pool plumbing – circulating water under pump pressure.

- Fire mains – carrying pressurized water to hydrants or sprinkler systems.

- Pump lines and rising mains – from wells or tanks.

➡️ Chosen for its high strength, leak-free joints, and corrosion resistance.

🚽 PVC DWV Pipe – Applications

Used in non-pressurized gravity systems:

- Building drainage systems – removing wastewater from sinks, toilets, and showers.

- Vent systems – equalizing air pressure in plumbing to prevent trap siphoning.

- Sewer lines – connecting buildings to municipal sewer networks.

- Stormwater drainage – roof downpipes and surface water collection.

- Sanitary waste systems – both residential and commercial plumbing.

➡️ Chosen for its smooth interior, ease of installation, and low cost.

Summary

PVC pressure pipe is designed to carry pressurized fluids, such as water for supply, irrigation, or industrial systems. It has thicker walls, is pressure-rated (commonly up to several hundred psi), and follows standards like ASTM D2466 or D2241. The joints are solvent-welded or threaded to ensure a watertight and pressure-resistant seal.

PVC DWV pipe, on the other hand, is made for non-pressurized systems such as drains, waste, and vent lines. It relies on gravity flow, has thinner walls, and is not pressure-rated. DWV pipe typically follows ASTM D2665 standards and uses solvent-welded or gasketed joints for easy assembly and maintenance.

✅ In short:

- Pressure pipe → For pressurized water flow (thicker, stronger, rated for pressure).

- DWV pipe → For drainage and venting (lighter, thinner, gravity-only).

About SAM-UK

SAM-UK are a professional 19+ years manufacturer in producing vinyl building profile products and PVC , CPVC , PPH , PPR , PP pipes and pipe fittings, valves, taps and so on. We own the certificates of SGS\SONCAP\ISO9001\CE\NSF,support color /size customization. Welcome to consult for Catalog and Product. you can contact us at email [email protected]