Introduction

For manufacturers of PVC, CPVC, and PPR pipes, consistent quality isn’t just a goal—it’s a prerequisite for safety, reliability, and market reputation. A single batch failure can lead to costly recalls, project delays, and damage to brand trust.

While the raw materials differ, the philosophy of robust Quality Control remains the same. This article outlines the five non-negotiable QC tests that every reputable pipe producer must perform to guarantee their products can withstand the demands of pressure, temperature, and time.

The 5 Essential Quality Control Tests

Here is a summary of the core tests, each critical for different aspects of performance:

| Test Name | Primary Purpose | Key Standard(s) (Examples) |

|---|---|---|

| 1. Dimensional Inspection | Ensures that the pipe’s outer diameter, inner diameter, wall thickness, and length meet specified tolerances. | STM D1598, ISO 1167 |

| 2. Hydrostatic Pressure Test | Verifies the pipe’s ability to withstand internal pressure without leakage or bursting. | ASTM D1525, ISO 306 |

| 3. Tensile Strength & Elongation Test | Measures the material’s resistance to pulling forces and its ability to deform without breaking. | ASTM D2444, ISO 3127 |

| 4. Impact Resistance / Notch Test | Evaluates the pipe’s resistance to sudden impacts, which can occur during transport or installation. | ASTM D1238, ISO 1133 |

| 5. Chemical & Thermal Resistance Test | Ensures the pipe can withstand exposure to water, hot fluids, and chemicals as per application standards. | ASTM D1603, ASTM D5596 |

Detailed Breakdown of Each Test

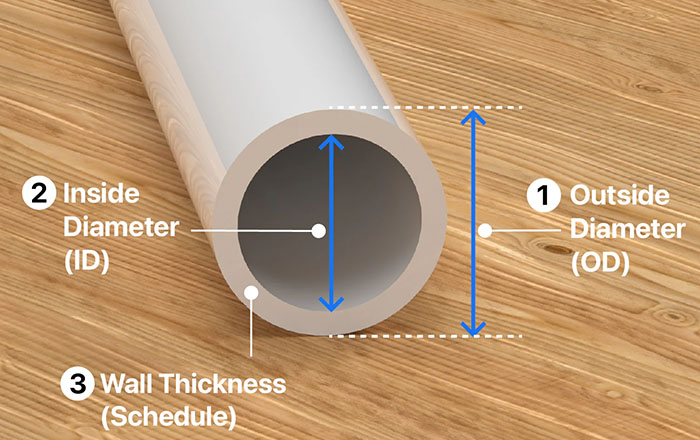

1. Dimensional Inspection

Purpose: Ensures that the pipe’s outer diameter, inner diameter, wall thickness, and length meet specified tolerances.

How to Test:

- Use calipers or laser measuring devices for diameter and wall thickness.

- Measure pipe length and check straightness using a straightedge.

Why It Matters: Accurate dimensions guarantee proper fitting, joint integrity, and compliance with standards such as ASTM D1785 (PVC) or ISO 15874 (PPR/CPVC).

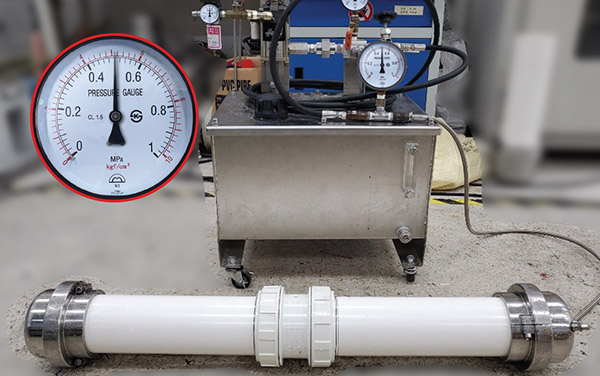

2. Hydrostatic Pressure Test

Purpose: Verifies the pipe’s ability to withstand internal pressure without leakage or bursting.

How to Test:

- Fill the pipe with water and apply the specified test pressure (usually 1.5× working pressure).

- Maintain the pressure for a defined period (e.g., 2–24 hours).

Why It Matters: Confirms strength and safety for water supply or industrial fluid transport applications.

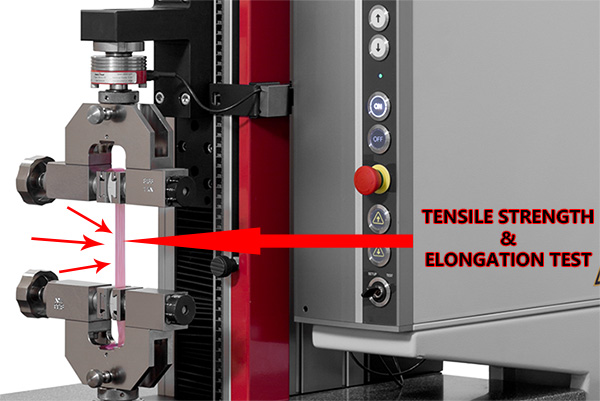

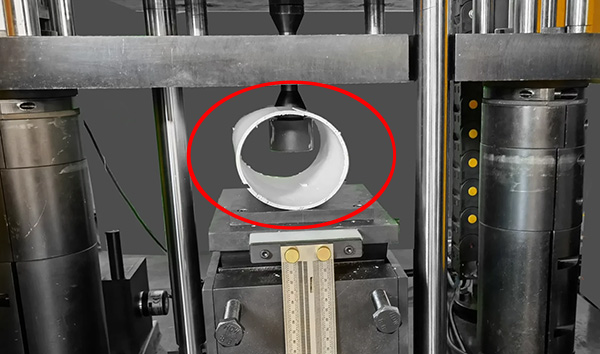

3. Tensile Strength & Elongation Test

Purpose: Measures the material’s resistance to pulling forces and its ability to deform without breaking.

How to Test:

- Cut standardized pipe specimens.

- Use a tensile testing machine to determine tensile strength and elongation at break.

Why It Matters: Ensures the pipe material can handle mechanical stresses during installation and operation.

4. Impact Resistance / Notch Test

Purpose: Evaluates the pipe’s resistance to sudden impacts, which can occur during transport or installation.

How to Test:

- Conduct an Izod or Charpy impact test on pipe samples.

- Some manufacturers also perform a drop weight test for larger pipes.

Why It Matters: Prevents cracks, fractures, or failures in real-world handling conditions.

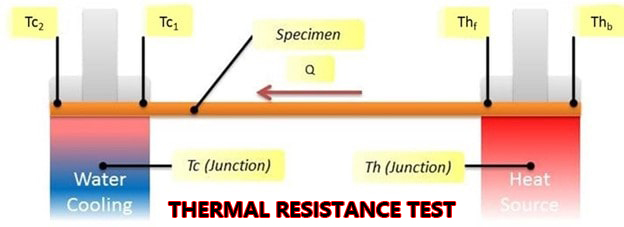

5. Chemical & Thermal Resistance Test

Purpose: Ensures the pipe can withstand exposure to water, hot fluids, and chemicals as per application standards.

How to Test:

- Expose pipe samples to hot water (for CPVC/PPR) or chemicals relevant to intended use.

- Observe for changes in strength, color, or surface quality.

- Thermal testing includes heat deflection temperature and long-term hydrostatic strength tests.

Why It Matters: Confirms the pipe’s durability in high-temperature or chemically aggressive environments.

summary

Conclusion: Quality is a Process, Not a Single Test

Implementing these five key tests forms the bedrock of a trustworthy manufacturing process for PVC, CPVC, and PPR pipes. By rigorously adhering to these and other relevant ASTM, ISO, and national standards, manufacturers can deliver products that engineers specify with confidence and installers trust on the job site.

Remember, a comprehensive QC program doesn’t just catch defects—it builds a reputation for unwavering reliability.

About SAM-UK

SAM-UK are a professional 19+ years manufacturer in producing vinyl building profile products and PVC , CPVC , PPH , PPR , PP pipes and pipe fittings, valves, taps and so on. We own the certificates of SGS\SONCAP\ISO9001\CE\NSF,support color /size customization. Welcome to consult for Catalog and Product. you can contact us at email [email protected]