Article Introduction

There is always a confusion about the terms bends and elbows. They are frequently used as synonyms, but not same.

Elbow is a standard fitting but bends are custom fabricated. Bends are generally made or fabricated as per the requirement; however elbows are pre-fabricated and standard.

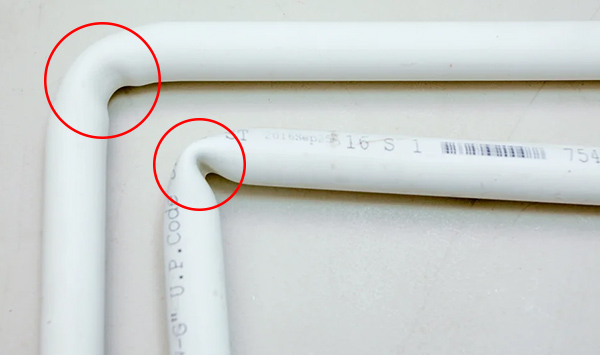

The major difference is the radius of curvature. Elbows generally have radius of curvature between one to twice the diameter of the pipe. Bends have a radius of curvature more than twice the diameter. Elbows have industrial standards and have limitations to size, bend radius and angle. The angles are usually 45 deg or 90 degrees. All others offsets are classified as pipe bends.

By reading the following article, you can learn more about elbows and pipe bends !

When is PVC pipe elbow ?

The pvc pipe elbow is used for a horizontal right angle connection with the draining horizontal pipe or the drainage riser. Generally speaking, 45° and 90° elbows are more commonly used.

- The 45 degree elbow is pipe fittings and pipe fittings. It is used in main pipe and branch pipe. To change the direction of the pipeline.

- The 45 degree elbow commonly used in daily life is basically made of PVC material. Because of its good quality, it is more convenient to use.

- PVC 45 degree elbow and pipe connection methods are: direct welding (the most commonly used way) flange connection, hot melt connection, electric melt connection, threaded connection and socket connection. According to the production technology, it can be divided into: welding elbow, stamping elbow, pushing elbow, casting elbow and so on.

- PVC 90 degree elbow is a kind of pipe fittings commonly used in water heating installation. It is used to connect the bends of pipes and change the direction of pipes.

- Other names: 90 degree elbow, right angle elbow, love and bend, stamping elbow, pressing elbow, machine elbow, welding elbow, etc.

- Purpose: Connecting two pipes of the same nominal diameter or different sizes, making the pipes bend 90 degrees and various degrees.

What is a PVC pipe bend ?

The flow of a PVC pipe bend is usually better and smoother because of the lack of irregular surfaces inside it. The substance flowing inside does not have to change its direction abruptly due to sharp turns or twists. It has a wider regular pipe bend radius, accommodating the flow better than a pipe elbow.

Builders prefer to use pipe bends because they are affordable and do not usually need many expensive fittings. They also work for any purpose to which you can put a pipe elbow, but they do not cost as much. You can always change their direction if you use cold or hot bending on a bending machine.

The difference between elbows and bent pipes

1. Category

A pipe bend is a general term used for changing the flow of a piping system. But a pipe elbow is an engineering term with specific classifications: radius type and degree. You do not find the same with bends.

2. Manufacture

An engineer or contractor makes a pipe bend depending on the moment’s need; it does not come pre-designed that way. On the other hand, a pipe elbow is manufactured with detailed standard specifications, and you can find it in stores for picking.

3. Classification

You can classify all pipe elbows as bends because of the tangent; a bend is a general term for pipe bends and pipe elbows. The pipes come bent, which is the general term for their direction. But you cannot classify all pipe bends as elbows because bends are custom-made, but elbows are not.

4. Angles

Pipe elbows are restricted in how much they can change directions. You buy them already fitted to industry standards. So, they are limited in angle, bend radius, and size. All elbows maintain a 45-degree or 90-degree bending angle. Pipe bends are more flexible, and any other offset on a pipe makes it a bend, not an elbow.

5. Flow

Some elbows have a 180-degree angle, making them a return bend because of the total flow reversal. However, almost all elbows have sharp corners due to their specific right angles and design. On the other hand, bends never have sharp corners but always have a smooth flow.

6. Friction

There is usually less pipe friction involved when forging a bend. The reason is that you do not need to weld, screw, or flange the pipe. Also, there is no frictional fluid pressure loss. However, elbows usually need welding or screwing to connect them to the rest of the piping system, meaning they can create friction.

7. Thickness

There are constraints on pipe bending to prevent a loss of thickness on piping material. The thinner a pipe is, the less able it is to contain the pressure of the fluid. Therefore, there is a requirement for the thickness a pipe must maintain to enable it to hold the pressure of the substance it carries. If there is a standard thickness, there will be less pressure drop.

What size PVC will bend?

PVC pipe can be bent using heat, but not all sizes bend equally well. The smaller the diameter, the easier it is to bend without collapsing or kinking.

🔧 General Guidelines for Bending PVC:

| PVC Pipe Size (Diameter) | Bendability | Notes |

|---|---|---|

| ½ inch (15mm) | ✅ Easy | Very flexible, good for tight curves |

| ¾ inch (20mm) | ✅ Easy | Still quite flexible with gentle heat |

| 1 inch (25mm) | ✅ Moderate | Can be bent smoothly with proper technique |

| 1¼ – 1½ inch | ⚠️ Tricky | Needs more heat and internal support |

| 2 inch and up | ❌ Difficult | Tends to kink or collapse, not ideal for bending |

🛠️ Tips for Successful Bending:

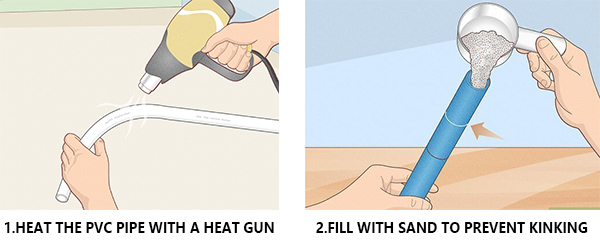

- Use a heat gun or hot sand method (not open flame).

- Support the interior with a flexible spring or sand to prevent collapse.

- Avoid overbending — keep bends above the pipe’s minimum bend radius.

- Use Schedule 40 PVC — it’s more flexible than Schedule 80.

🧱 Alternative for Large Pipes:

- For larger diameters (2”+), it’s usually better to use fittings (like elbows or sweeps) instead of bending.

How to bend a PVC elbow?

PVC elbows are pre-molded fittings—they’re not meant to be bent. If you’re asking how to change the angle of a PVC bend or create a custom bend, it’s important to clarify:

🔧 If you’re talking about bending PVC pipe, not the elbow:

- You can bend straight PVC pipe using heat to make custom curves. But an elbow (like 90° or 45°) is a rigid molded fitting and cannot be reshaped by bending.

❌ Why you can’t bend a PVC elbow:

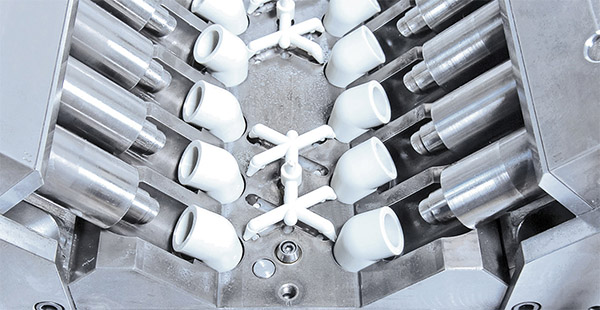

- PVC elbows are injection molded into their final shape.

- Trying to heat and bend an elbow will likely warp or destroy it.

- They have different wall thicknesses and internal stress points, making uniform bending impossible.

✅ Alternative Solutions:

1. Use Heat to Bend PVC Pipe Instead

- If you need a custom angle:

- Use a heat gun to soften straight PVC pipe.

- Bend it over a jig or form.

- Let it cool and harden in place.

2. Use Multiple Elbows

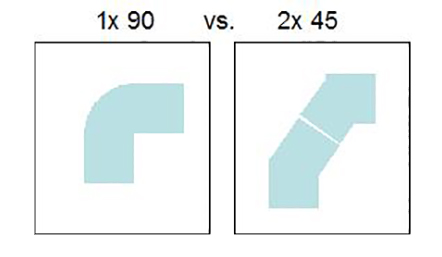

- If a standard 90° or 45° elbow doesn’t suit your need:

- Combine two 45° elbows to make a 90° with a slight offset.

- Use street elbows or adjustable fittings for custom directions.

Notes:

You cannot bend a PVC elbow—only straight pipe can be bent with heat. For directional changes, choose the correct elbow fitting or consider flexible pipe alternatives.

Will PVC break if bent?

Yes, PVC will break if bent improperly — especially if it’s cold or bent too sharply without heating.

🔍 Why PVC Breaks When Bent:

- Rigidity PVC is a rigid thermoplastic. It’s designed to stay straight.

- Temperature Cold PVC becomes brittle and snaps more easily.

- Sharp Bend Radius Bending too tightly causes cracking or creasing.

- No Internal Support Without filling (e.g. with sand), pipe walls may collapse.

✅ When Can You Bend PVC Without Breaking It?

- It’s softened using controlled heat (e.g. heat gun or oven).

- The bend radius is gradual, not sharp.

- You optionally fill it with sand to prevent kinking.

- You allow it to cool in the desired shape without forcing.

❌ What Happens If You Bend It Cold?

- Hairline cracks may form (not visible at first).

- It can snap suddenly under pressure or load.

- Even if it holds its shape, it loses strength at the bend point.

✅ Best Practice:

If you need bends, heat and shape PVC pipe, or use pre-molded elbow fittings or flexible PVC hose.

Summary

Therefore, elbows and bent pipes are two different types in essence, and their methods of use and effects are also different. When choosing to buy, you need to choose according to the actual usage scenario and the desired effect.

If you want to know more about pipes, you can consult SAM-UK pipe supplier and we will answer your questions !

About SAM-UK

SAM-UK are a professional 18+ years manufacturer in producing vinyl building profile products and PVC , CPVC , PPH , PPR , PPpipes and pipe fittings, valves, taps and so on. We own the certificates of SGS\SONCAP\ISO9001\CE\NSF,support color /size customization. Welcome to consult for Catalog and Product. you can contact us at email [email protected]