Introduction

💡 Whether it’s for home repairs, garden irrigation, or small projects, PVC piping is widely popular due to its lightweight, durable, and low-cost design. However, for beginners, the types, sizes, and connection methods of pipes can often be confusing. This guide systematically explains the basics and practical application of PVC piping to help you easily become a DIY expert.

1、Common Types of PVC Pipes

PVC pipes are categorized in several ways, with wall thickness being the most common:

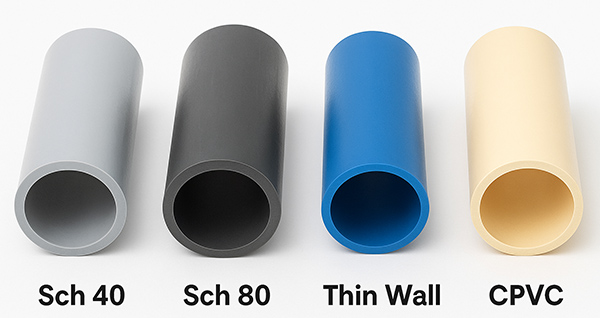

1. Schedule 40 (Sch 40)

- Most common pipe type

- Mostly white, used for drainage, irrigation, and cold water distribution

- Has a moderate pressure rating and is most commonly used in home DIY applications

2. Schedule 80 (Sch 80)

- Mostly gray, with thicker walls and greater pressure resistance

- Commonly used in industrial, factory, or high-pressure water distribution

- Slightly more expensive and heavier

3. Thin-wall PVC (DWV) pipe

- Mainly used for drainage and ventilation systems (Drain, Waste, Vent)

- Not suitable for pressure-bearing applications

- Lightweight, easy to cut and install

4. CPVC pipe (chlorinated polyvinyl chloride)

- Can withstand higher temperatures (up to approximately 90°C)

- Commonly used in hot water systems, but more expensive than standard PVC

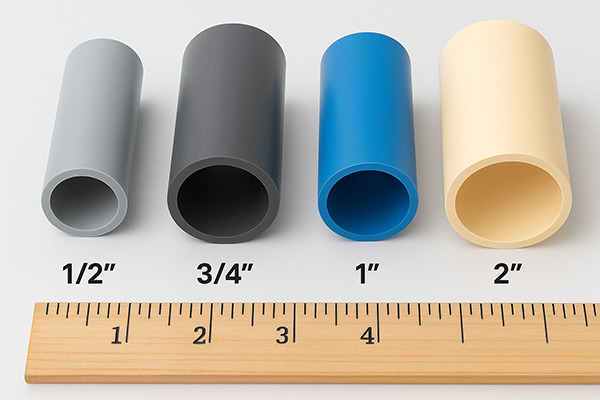

2、PVC Pipe Sizes and Specifications

PVC pipe sizes are primarily measured in inches. Common sizes include:

- Diameter Range: From 1/2″ to 12″

- Common household sizes: 1/2″, 3/4″, 1″, 1.5″, and 2″

- Wall Thickness and Pressure Rating: Sch 40 is suitable for standard water supply, while Sch 80 is suitable for higher pressure environments.

👉 Tip: When purchasing, pay attention to the difference between “inside diameter” and “outside diameter.” Fittings must match the corresponding pipe model.

3、PVC Pipe Connection Methods

1. Adhesive Connection (Most Common)

- Use PVC-specific solvent-based glue (primer + cement)

- Steps: Clean joint → Apply primer → Apply glue → Insert and rotate → Cure

- Advantages: Good sealing, easy operation

- Disadvantages: Once secured, cannot be removed

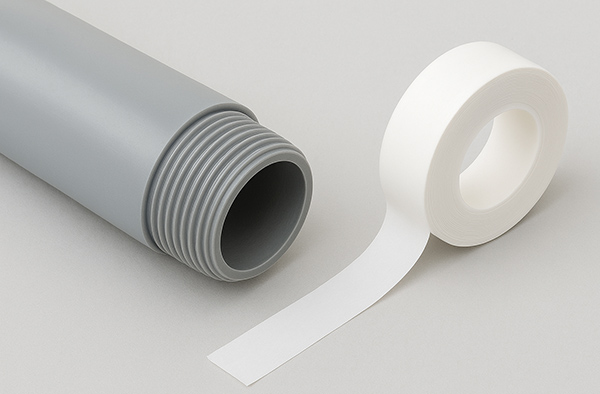

2. Threaded Connection

- Threaded pipe ends or fittings

- Reusable and often used for equipment connections

- Requires sealing tape (raw tape/PTFE tape) to enhance the seal

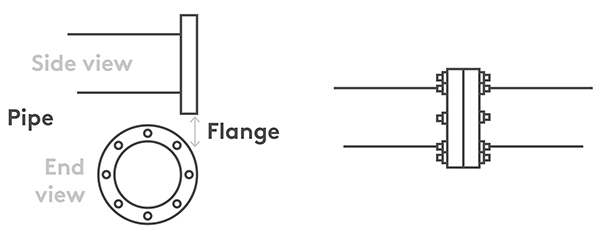

3. Flange Connection

- For large-diameter pipes

- Add a sealing gasket between the two flanges and secure with bolts

- Suitable for high-pressure applications

4. DIY Tool List

Having the right tools will make the process smoother:

- Cutting tool: PVC pipe cutter (recommended) or fine-tooth saw

- Chamfering tool: For removing burrs from cuts and preventing damage to the adhesive layer

- Tape measure & marker: For precise measurement and positioning

- Sandpaper/cleaning cloth: For cleaning joints and ensuring glue adhesion

- PVC primer & glue: Essential for connection

- Gloves & safety glasses: For safe operation

5. Safety Practices

1. Working Environment

- Maintain good ventilation to avoid prolonged inhalation of glue fumes.

- Avoid using adhesives near open flames or in high-temperature environments.

2. Personal Protection

- Wear gloves to prevent burns from the glue.

- Wear goggles to prevent contact with eyes during cutting.

3. Operational Precautions

- Maintain a vertical cut to ensure a tight joint.

- Avoid moving the pipe before the glue has cured.

- Do not use PVC pipes to transport high-temperature liquids or high-pressure steam.

6. Common Beginner Mistakes and How to Avoid Them

❌Mistake 1: Uneven Cuts → ✅Solution: Use a dedicated cutter and chamfer the edges

❌Mistake 2: Not Using Primer → ✅Solution: Primer softens the pipe and improves adhesion

❌Mistake 3: Applying Too Much or Not Enough Glue → ✅Solution: Apply evenly to avoid leaks and weak bonds

❌Mistake 4: Not Waiting for the Curing Time → ✅Solution: Wait at least 15 minutes before pressure testing

Conclusion

PVC pipe installation isn’t complicated. As long as you understand pipe types, size selection, proper connection methods, and follow tool preparation and safety regulations, even complete beginners can successfully complete any home or small project.

📌This “Ultimate DIY Guide to PVC Piping” is your first step toward becoming a DIY master!

About SAM-UK

SAM-UK are a professional 19+ years manufacturer in producing vinyl building profile products and PVC , CPVC , PPH , PPR , PP pipes and pipe fittings, valves, taps and so on. We own the certificates of SGS\SONCAP\ISO9001\CE\NSF,support color /size customization. Welcome to consult for Catalog and Product. you can contact us at email [email protected]