Article Introduction

Many consumers have no idea that PVC or polyvinyl chloride is a type of plastic. They also do not know that it serves a wide range of other applications apart from piping to deliver cold and hot water. It is used to make shower curtains, imitation leather, fittings to transfer chemicals, and even window frames. It can also be used for plumbing systems, gutters, home siding, medical pipe tubing, as well as skiing equipment. But there are also other kinds of plastics other than PVC and provided below is a brief discussion about plastics. Including the differences between the most common ones.

What is PVC (Polyvinyl Chloride)

PVC (Polyvinyl Chloride) pipe is a type of plastic piping commonly used in plumbing, irrigation, and construction. It’s made from a synthetic polymer that’s lightweight, durable, and resistant to corrosion, making it an excellent alternative to metal pipes. PVC pipes are often used for both cold and hot water systems, as well as for drainage, sewer systems, and electrical conduit.

Core material – PVC plastic:

- A thermoplastic formed by the polymerization of vinyl chloride monomer.

- It is hard in itself, but can be made soft by adding plasticizers (soft PVC).

- Pipes usually use unplasticized hard PVC (uPVC or PVC-U), which has high strength, rigidity and durability.

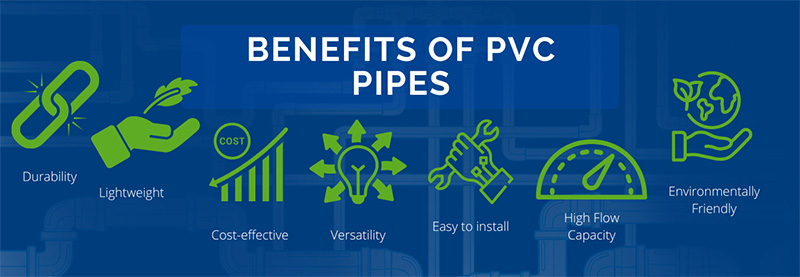

PVC pipe Main advantages:

- Strong corrosion resistance: One of the biggest advantages. Unlike metal pipes (iron, copper), it will not rust or be corroded by chemicals. It is particularly suitable for conveying water (especially chlorinated tap water), drainage, corrosive chemicals, industrial wastewater, etc.

- Lightweight: The weight is much lower than that of metal pipes (such as cast iron pipes and steel pipes). It is easy and quick to carry and install, reducing labor costs and transportation costs.

- Smooth inner wall: Small water flow resistance, not easy to scale, good water flow capacity, and small flow loss in long-term use.

- Good insulation: Good electrical insulation, often used as protective casing (electrical casing) for wires and cables.

- High cost-effectiveness: The cost of raw materials is relatively low, and the installation is simple, so the overall cost is usually lower than that of metal pipes.

- Easy to process and connect: It is easy to cut (with a saw), and the connection method is simple and reliable (commonly used solvent-based adhesive bonding, rubber sealing ring socket connection or threaded connection).

- Long service life: Under appropriate application conditions, the service life can reach 50 years or even longer.

- Low maintenance requirements: It is not easy to corrode and scale, and almost no maintenance is required.

- Flame retardant: Rigid PVC itself is self-extinguishing (it will extinguish when leaving the fire source).

PVC pipe Main types and applications:

- Water supply pipe: Used to transport drinking water and domestic water. There are strict safety and sanitation standards (such as meeting NSF/ANSI 61 standards). Common colors are White PVC water supply pipe and Gray PVC water supply pipe.

- Drainage/sewage pipe: Used for wastewater discharge in buildings (indoor drain pipes) and underground drainage/sewage systems (outdoor drain pipes), The pipe wall is thinner than the water supply pipe. Usually PVC white drainage pipe and PVC gray drainage pipe.

- Rainwater pipe: The main function of PVC rainwater pipes is to collect rainwater from roofs, balconies or other building surfaces, and guide it safely and effectively to the ground drainage system or designated collection points.

- Electrical Conduit/Wire Duct: PVC has good insulation properties, so it can also be used well in the electrical field, including PVC wire tubes、PVC wire tube joints、PVC wire boxes.

Specifications and standards:

PVC pipes have strict size standards (outer diameter, wall thickness) and pressure grades (such as SCH 40, SCH 80 represent different wall thickness and pressure capacity).

Must comply with relevant national or international standards (such as ISO, ASTM, GB, etc.) and safety standards for specific application areas (such as drinking water hygiene standards).

Summary:

In summary, PVC pipe is a kind of pipe made of rigid polyvinyl chloride plastic, which is economical, lightweight, corrosion-resistant and easy to install. It is widely used in cold water transportation, drainage and sewage, wire protection and industrial fluid transportation, and is an indispensable part of modern pipeline engineering. However, when choosing, it is important to consider its temperature limit, impact resistance (especially in low temperature environment) and pressure requirements.

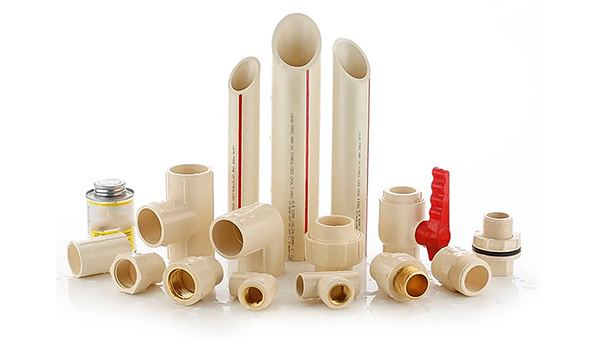

What is CPVC (chlorinated polyvinyl chloride)

CPVC pipe stands for Chlorinated Polyvinyl Chloride pipe. It is a thermoplastic piping material made by chlorinating regular PVC (Polyvinyl Chloride) resin. This added chlorine increases the material’s temperature resistance and durability, making it suitable for both hot and cold water distribution systems.

Key Features of CPVC Pipes:

| Property | Description |

|---|---|

| Temperature Resistance | Can handle temperatures up to 200°F (93°C) — higher than regular PVC. |

| Corrosion Resistance | Highly resistant to corrosion, scale, and chlorine-based chemicals. |

| Longevity | Long service life — often 50+ years under proper installation and use. |

| Smooth Interior | Reduces friction loss and maintains water pressure over time. |

| Easy Installation | Lightweight, easy to cut and solvent weld, saving time and labor. |

Common Applications:

-

Hot and cold potable water systems in residential, commercial, and industrial buildings.

-

Chemical handling systems due to its resistance to acids and alkalis.

-

Fire sprinkler systems (CPVC is UL listed for certain fire suppression systems).

CPVC vs PVC:

| Feature | CPVC | PVC |

|---|---|---|

| Max Temp | ~200°F (93°C) | ~140°F (60°C) |

| Usage | Hot & cold water, chemicals | Cold water, drainage, vents |

| Cost | Slightly more expensive | More affordable |

| Color | Typically off-white/tan | Usually white or gray |

So CPVC pipe is a high-performance thermoplastic pipe, which has been widely used in hot water supply, industrial fluid transportation, and fire sprinkler systems due to its excellent high temperature resistance, excellent chemical corrosion resistance, flame retardancy, relatively easy installation, and cost-effectiveness. It is an upgraded substitute for ordinary PVC in applications that require higher temperatures and stronger chemical resistance.

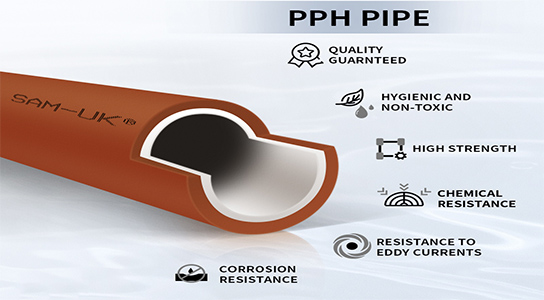

What is PPH(Polypropylene)

PPH stands for Polypropylene Homopolymer, and PPH pipes are made from a type of polypropylene that is specifically designed for higher strength and durability compared to other forms of polypropylene. PPH pipes are typically used in industries where chemical resistance and high-temperature performance are important.

They are often used in:

- Chemical transport: Due to their strong chemical resistance, they are ideal for transporting chemicals, acids, and other aggressive liquids.

- Water treatment: PPH pipes are resistant to corrosion and scaling, making them suitable for water treatment plants.

- Industrial systems: They can handle high-pressure environments and can be used for transporting both hot and cold fluids.

In terms of their characteristics:

- High thermal stability: They can handle temperatures up to about 90°C (194°F).

- Good resistance to impact: PPH pipes have high tensile strength and resist mechanical stresses.

- Easy installation: They are lightweight, making them easier to handle and install than some other materials.

These pipes are generally available in a range of sizes and are used for both low and medium-pressure systems.

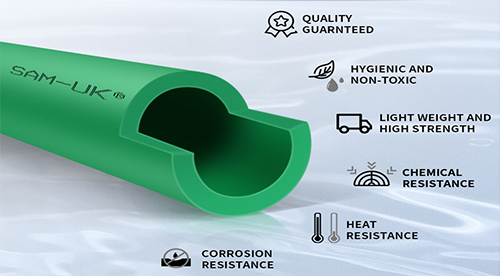

What is PPR (Polypropylene-Random)

PPR pipe refers to a plastic pipe system made of random copolymer polypropylene (Polypropylene Random Copolymer). It is widely used in hot and cold water transportation systems, drinking water systems, heating systems (such as floor heating), air conditioning systems and some industrial fluid transportation in buildings.

Key Features of PPR Pipes:

-

Temperature Resistance: PPR pipes can handle temperatures up to about 95°C (203°F), making them ideal for hot water systems.

-

Durability: They have a long service life (usually 50+ years) and are resistant to scale buildup, corrosion, and UV damage.

-

Chemical Resistance: PPR pipes resist a wide range of chemicals, making them suitable for various industrial applications.

-

Smooth Surface: The internal surface is smooth, reducing friction and making them more efficient for water flow.

-

Easy Installation: PPR pipes are joined using heat fusion, making the installation process easier and eliminating the need for adhesives or glues.

Main application areas:

- Building water supply system: cold water, hot water supply, especially domestic drinking water pipelines.

- Heating system: radiator connecting pipes, main pipes and coils of floor heating (floor heating) pipes (usually use smaller diameter and more flexible PERT pipes, but PPR pipes are often used for main pipes).

- Central air conditioning system: chilled water, cooling water pipelines.

- Industrial fluid transportation: certain chemical liquids, gases, compressed air, etc. that are not corrosive to materials.

- Pure water, drinking water treatment system.

- Agricultural irrigation.

- Solar water heater system.

PPR pipes have become one of the most mainstream and popular plastic pipe solutions in modern building hot and cold water systems (especially hot water and heating systems) due to their high temperature resistance, pressure resistance, sanitation and non-toxicity brought by random copolymer polypropylene materials, as well as ultra-high sealing and reliability brought by the revolutionary hot-melt connection method. Its comprehensive performance, safety and economy are very outstanding.

What is the difference between them?

Each type of pipe has its own strengths, so selecting the right one depends on factors like the temperature of the fluid, the environment (outdoors or indoors), and the specific application (residential vs. industrial).

Summary comparison table:

| Characteristics | PVC | CPVC | PPH | PPR |

|---|---|---|---|---|

| Chemical nature | Polyvinyl chloride | Chlorinated polyvinyl chloride | Polypropylene (homopolymer) | Polypropylene (random copolymer) |

| Biggest Advantage | Low cost and mature drainage application | High temperature hot water (heat resistance far exceeds PVC) | Strong chemical resistance | Hot and cold water supply (toughness, long life) |

| Maximum operating temperature | ~60°C (140°F) | 90-100°C (195-212°F) | 90-100°C (195-212°F) | 70-80°C (160-175°F) |

| Chemical resistance | Good (except some solvents) | Good (slightly better than PVC) | Excellent (best among polypropylene) | Good (not as good as PPH) |

| Rigidity/toughness | High rigidity, low toughness | High rigidity, low toughness | High rigidity, high brittleness at low temperature | Moderate rigidity, high toughness/impact resistance |

| Main connection method | Solvent bonding | Solvent bonding | Butt welding/Electrofusion welding | Hot melt socket welding |

| Typical Applications | Drainage, sewage, cold water, threading | Hot water pipes, industrial high temperature fluids, fire protection | Highly corrosive industrial pipelines, high-purity water | Building hot and cold water pipes, drinking water, HVAC |

| Cost | lowest | Medium (higher than PVC) | Medium to high | medium |

Simple selection guide:

- Household/building cold water/drainage/sewage/ventilation/wiring: PVC PIPE (most economical).

- Household/building/industrial hot water supply: CPVC PIPE (good high temperature resistance) or PPR PIPE (good toughness, long life, easy installation).

- Industrial transportation of highly corrosive chemicals: PPH PIPE (best chemical resistance) or CPVC PIPE (good comprehensive temperature and chemical resistance).

- Building hot and cold water mains, drinking water, heating: PPR PIPE (best overall performance, mainstream choice).

- High-purity water system: PPH PIPE or PPR PIPE (high purity level required).

When choosing, be sure to consider the specific fluid medium, operating temperature, operating pressure, environmental conditions, relevant national/industry standards and cost budget. For critical applications, it is recommended to consult the specific performance data sheet of the material or consult a professional engineer.

About SAM-UK

SAM-UK are a professional 18+ years manufacturer in producing vinyl building profile products and PVC , CPVC , PPH , PPR , PP pipes and pipe fittings, valves, taps and so on. We own the certificates of SGS\SONCAP\ISO9001\CE\NSF,support color /size customization. Welcome to consult for Catalog and Product. you can contact us at email sales@sam-uk.com