Article Introduction

Elbows pipe are used to connect two pipes that are at a right angle to one another. On a level installation, they serve as corner or railing ends. In other words, pipe elbow is easily connected to pipes made of so many different materials, including rubber, steel, cast iron, copper, and plastic. This pipe-fitting device is bent in such a way as to cause a Different angles change in the direction that the fluid or gas flows through the pipe. The elbow, which is also referred to as a “quarter bend,” is a pipe fitting used to shift direction.

As a professional plastic pipe & fittings 18+ years manufacturer, we offer various of PVC pipe elbows to customers. Through the following articles, You can learn about the applications of our various PVC elbow pipe fittings.

What angle do PvC elbows come in?

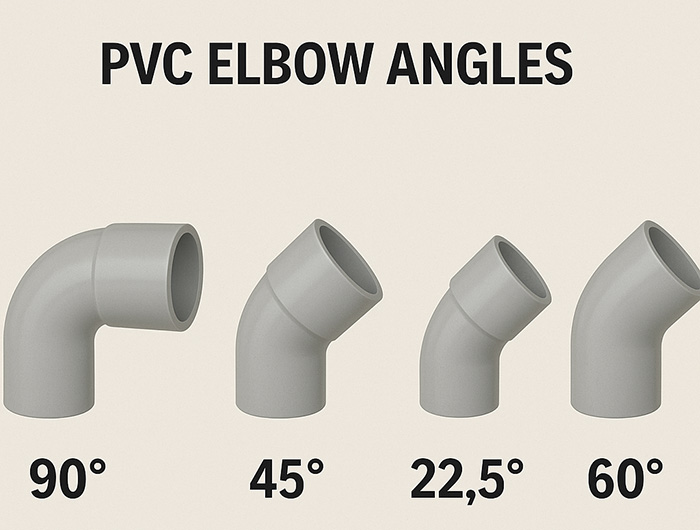

PVC elbows come in a variety of standard angles, each designed to redirect pipe flow by a specific amount. The most common angles for PVC elbows include:

🔄 Standard PVC Elbow Angles:

| Elbow Angle | Description | Common Use |

|---|---|---|

| 90° (Right Angle) | Makes a sharp, perpendicular turn | Most common; water supply, drain lines |

| 45° | Makes a smoother, gentler turn | Reduces flow resistance; drainage systems |

| 22.5° | Slight directional change | Fine-tuning pipe routes |

| 60° (less common) | Steeper turn than 45°, not as sharp as 90° | Used in special layouts or tight spaces |

| 30° or 11.25° (rare) | Very minor direction changes | Specialized irrigation or custom systems |

🛠️ Notes:

Some fittings come pre-molded at these angles.

For custom angles, professionals may combine two elbows (e.g., two 45° = 90°) or use flexible couplings.

Commonly used PVC pipe elbow angles

PVC pipe elbow is a plastic product made by plastic injection molding machine of raw material polyvinyl chloride, which is the connector of PVC pipe. Generally 90 degrees and 45 degrees. Insert the two pipes into the angled connector. This connector is called elbow. The PVC pipe elbow is used in many residential construction, home drainage systems mainly use 90°elbow , 45° elbow, take more rigid PVC pipe. PVC 90°elbow and PVC 45°elbow are used for drainage. The PVC pipe elbow is glued to the pipe by a special glue or adhesive bonding.

PVC Elbow Application Description

90° PVC pipe elbow and 45°PVC pipe elbow applied to the pipe end turn. In the actual work experience, the 90°PVC pipe elbow takes up the space is little, the circulation effect and the impact is big;45°PVC pipe elbow to take up the space is large, but the circulation effect is good, if the space is large, suggest using 45 ° elbow joint turn into big radian. You can choose the right size PVC pipe elbow according to your piping condition.

About U type、S type and P type of PVC pipe elbow

PVC U type, PVC S type, PVC P-type PVC pipe elbow is a function of stink (they can also be called water trap). For example, the kitchen sink is drained with PVC S type water trap, the urinal is drained and the PVC P-type water trap is bent, and the washbasin is often used to drain the water. No matter which kind of water storage elbow, as long as the guarantee of the water level height, can get a very good odor separation effect.

In addition, it is important to note that in the home improvement project, the gap between the water and the water in the urinal should be enough, otherwise, it is easy to drain the water and slow the use of the urinal.

What is the difference between a PVC elbow and a street elbow?

The difference between a PVC elbow and a street elbow lies in how they connect to other fittings or pipes:

🔹 PVC Elbow (Standard Elbow):

- Ends: Both ends have female slip (socket) or female threaded connections.

- Use: Connects two pipes directly.

- Connection: You need a pipe on both ends to fit into the elbow.

Example: One pipe into each side of the elbow.

🔸 Street Elbow:

- Ends: One end has a female connection (socket or thread), the other end has a male connection (spigot or thread).

- Use: Connects directly to another fitting without needing a short piece of pipe.

- Connection: One end goes into another fitting, and the other receives a pipe.

Example: A street elbow can plug directly into a standard elbow, saving space and material.

🔧 Tip:

Street elbows are especially useful in tight spaces or when making compact turns in piping systems. However, they’re not always allowed in some plumbing codes, so double-check if you’re doing regulated installations.

Why are PVC elbows so expensive?

PVC elbows can seem expensive for several reasons, even though they’re made from relatively low-cost materials. Here’s why:

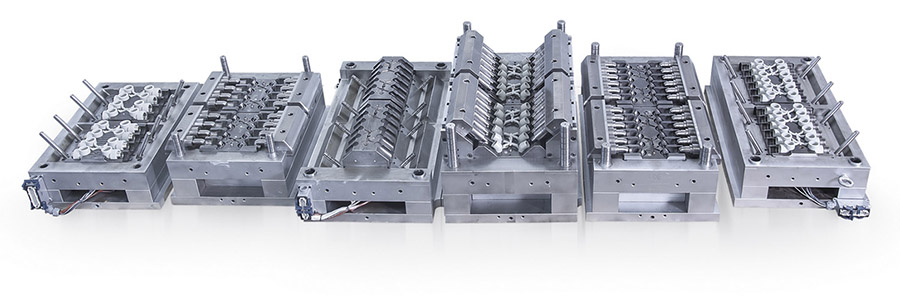

🔍 1. Mold & Tooling Costs

- PVC elbows are made with precision molds that are costly to design and maintain, especially for complex shapes (like reducing or threaded elbows).

- The cost of tooling is spread across the parts produced, so lower-volume items (uncommon angles or sizes) are more expensive.

🧱 2. Material Quality

- Some elbows use virgin PVC or CPVC for pressure-rated systems, which is more expensive than recycled PVC.

- Higher-grade formulations (e.g. UV-resistant or hot-water-rated) cost more.

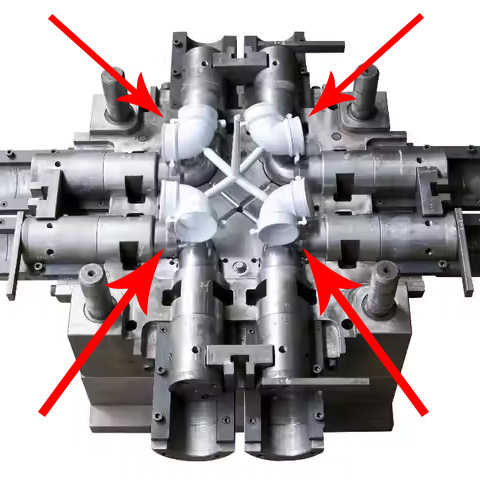

🏭 3. Manufacturing Complexity

- Elbows require multi-directional molding and sometimes post-processing (e.g., threading), which adds labor and time.

- Quality control is stricter to prevent leaks at angle changes.

🚚 4. Logistics and Packaging

- Elbows take up more space than straight pipe (because of their shape), leading to higher storage and shipping costs per piece.

- They’re also more likely to be individually wrapped or protected, adding to packaging expenses.

🧩 5. Market Dynamics

- Low competition or brand-name fittings can drive prices up.

- Specialty elbows (e.g. large-diameter, chemical-resistant) often serve niche markets with less price sensitivity.

⚙️ 6. Standards & Certifications

- Many elbows must meet industry or building code certifications (NSF, ASTM, ISO), which require testing and documentation, adding cost.

Summary

Put it simply,PVC pipe elbows are a sort of pipe fitting that connects two pipes, The primary goal is to alter the path of events. As we all know, PVC elbows come in a variety of degrees. The most common are 45 degrees, 90 degrees, and 180-degree pipe elbows. In case of exceptional requirements, pipeline systems also use other degrees like 60° or 120°.

About SAM-UK

SAM-UK are a professional 18+ years manufacturer in producing vinyl building profile products and PVC , CPVC , PPH , PPR , PP pipes and pipe fittings, valves, taps and so on. We own the certificates of SGS\SONCAP\ISO9001\CE\NSF,support color /size customization. Welcome to consult for Catalog and Product. you can contact us at email [email protected]